Table of Contents

In the ever-evolving world of interior materials, choosing the right product can make a significant difference in both aesthetics and functionality. Cultured Marble emerges as an excellent solution, combining the luxurious beauty of natural stone with superior properties designed to serve real-life needs. At Vina PolyStone, with the foundation of over 21 years of experience from Nhat Huy Group, we are proud to offer top-quality Cultured Marble products, manufactured in Vietnam and supplied globally.

This article is a comprehensive guide to help you understand Cultured Marble, from its composition, Vina PolyStone’s unique production process, to common applications and why this material has become a smart choice for construction and renovation projects.

What is Cultured Marble? What is its composition?

Cultured Marble is not natural stone extracted directly from the earth; it is an engineered stone created through an advanced technical process. The main components of it include:

- Calcium Carbonate Powder (CaCO3): This is the core, making up the majority of the weight and providing the appearance and feel similar to natural marble. At Vina PolyStone, we use high-purity CaCO3 powder, extracted and processed within Nhat Huy Group’s closed supply chain, ensuring superior quality and consistency.

- Polyester Resin: Acts as a binder, linking the stone powder particles together. The quality of the resin directly affects the durability, waterproofing, and functionality of the product.

- Colorants and Additives: Added to create a variety of colors, stone veins, and improve other technical properties such as hardness and UV resistance.

Explore our CaCO3 Powder Supplier: Global Minerals.

The precise blending of these components according to a proprietary formula, along with a tightly controlled production process, creates Cultured Marble material with superior advantages over natural stone in many aspects.

Discover more about Cultured Marble made in Vietnam for the World

Cultured Marble Production Process at Vina PolyStone

At Vina PolyStone, we apply modern and advanced production processes to create Cultured Marble products that meet international standards. This process includes several key stages:

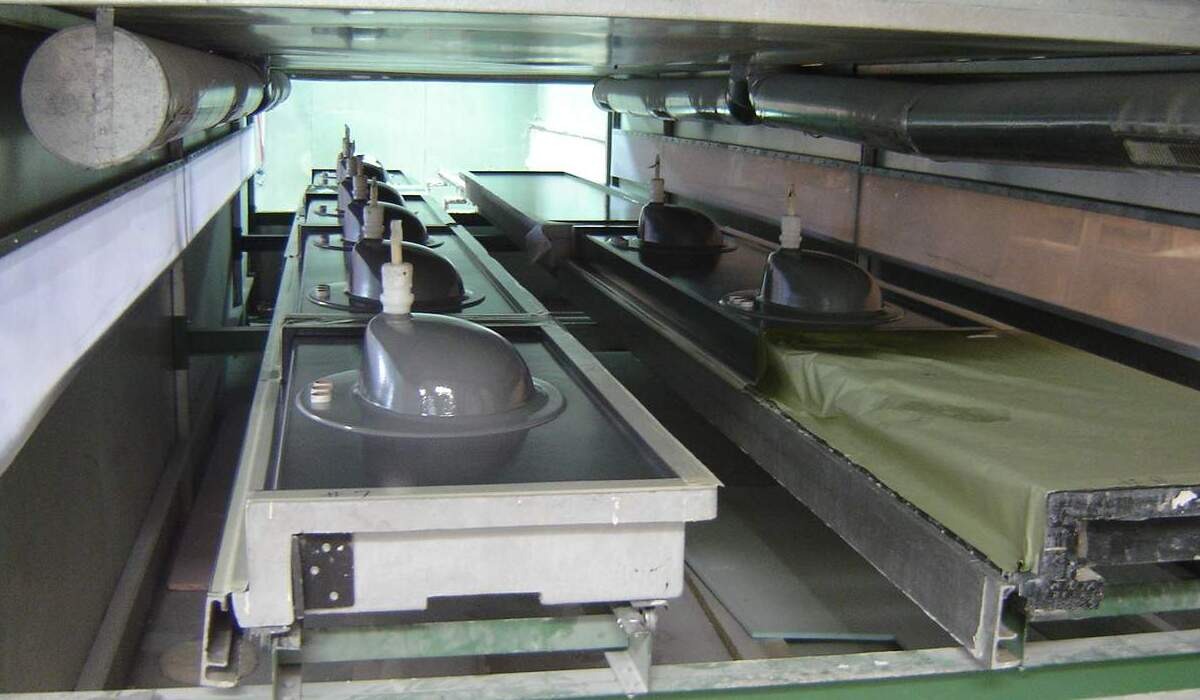

- Material Mixing: CaCO3 powder, resin, colorants, and additives are placed into specialized mixing tanks. We use a Vacuum Mixing System to completely eliminate air bubbles in the mixture. This is crucial as it ensures the material becomes dense and pore-free after curing, increasing durability, waterproofing, and providing a smoother surface finish.

- Casting: The mixed material is poured into meticulously designed molds. Depending on the product (vanity tops, bathtubs…), the mold can be simple for flat sheets or complex for integrated products like vanity tops with built-in sinks. The special integrated casting technique creates seamless products without joints, enhancing aesthetics and eliminating gaps where dirt and bacteria can accumulate.

- Gel Coating: This is one of the most important stages that gives Cultured Marble its superior properties. A specialized liquid Gel Coat (usually special polyester resin) is applied to the mold surface before pouring the stone mixture. This Gel Coat layer, once cured, forms a hard, durable, high-gloss finish that is waterproof and stain-resistant. It acts as a surface protection layer, providing seamless beauty and durability during use.

- Curing: After the mixture is poured into the mold and coated with Gel Coat, the material undergoes a curing process (drying and hardening). At Vina PolyStone, we can apply automatic drying or natural curing processes depending on the product type and technical requirements, ensuring the material achieves optimal hardness and durability.

- Finishing and Quality Inspection: After curing, the product is removed from the mold, trimmed to the required size, polished, and undergoes a rigorous quality inspection process. Each product is thoroughly checked for dimensions, shape, color, gloss, and surface defects before packaging.

Main Products from Cultured Marble at Vina PolyStone

Thanks to the flexibility in the production process and the properties of the material, Cultured Marble can be used to create various interior products, especially popular in bathrooms:

- Vanity Tops (Cultured Marble Vanity Tops): This is one of the most common applications. Cultured Marble vanity tops bring a luxurious, clean, and modern look to bathrooms. The biggest advantage is the ability to cast integrated sinks, creating a seamless design without joints, very easy to clean and completely waterproof. The Gel Coat surface is waterproof, stain-resistant, and easy to clean common stains like toothpaste and soap.

- Bathtubs (Cultured Marble Bathtubs): Cultured Marble bathtubs offer a luxurious relaxing experience. They are highly durable, retain heat better than some other materials, and can be cast into various shapes and sizes to fit any design space. The Gel Coat surface also helps the bathtub resist water, stains, and is easy to clean.

Additionally, Cultured Marble can be used for bathroom wall panels, window sills, and other interior decorative details.

Outstanding Advantages: Why Choose Cultured Marble?

Compared to natural stones like granite, marble, or other materials such as Quartz and Acrylic, Vina PolyStone’s Cultured Marble offers significant benefits:

- Superior Durability & Easy Maintenance: Thanks to the protective Gel Coat layer and dense internal structure (Made with High-purity Material for Superior Durability), Cultured Marble has excellent scratch and impact resistance. More importantly, its non-porous surface makes it waterproof and stain-resistant against common liquids like coffee, wine, and cosmetics. Daily cleaning is very simple, requiring only a soft cloth and mild detergent. There is no need for periodic maintenance, polishing, or sealing like natural stone. This is an effective integrated waterproof surface treatment!

- Seamless Beauty & Flexible Design: The ability to cast integrated pieces allows for seamless designs, eliminating grout lines or joints. This not only enhances aesthetics, providing seamless beauty, but also prevents mold and bacteria growth, making it very hygienic for wet environments like bathrooms. Cultured Marble also allows for a variety of colors and stone veins, realistically simulating the beauty of natural stone or creating unique color effects according to design requirements.

- Cost Efficiency: Compared to natural stone, Cultured Marble is generally more affordable. Especially when working directly with Vina PolyStone – an artificial stone manufacturer in Vietnam – you will receive cost-effective options with Cost-effective Choice with Factory-direct Pricing.

- Stable & Reliable Quality: Supported by Nhat Huy Group’s closed supply chain and over 21 years of experience, Vina PolyStone ensures stable quality for every batch. The production process is tightly controlled, from raw materials to the final product, providing consistency in color, size, and quality, which is difficult to achieve with natural stone.

Vina PolyStone: A Reliable Partner with Global Experience

Choosing Vina PolyStone is not just about selecting high-quality Cultured Marble products. It is about choosing a reliable partner, built on 21 years of trusted industry expertise. We understand the needs of the global market and are committed to providing the best solutions for our customers.

From pure stone powder controlled by the parent group, modern production processes with vacuum mixing systems, integrated casting techniques, and specialized Gel Coat application, to automatic drying processes and rigorous quality inspections – all aimed at creating durable, beautiful, easy-to-use Cultured Marble products with high economic value.

With global supply capabilities, Vina PolyStone is ready to meet orders of all sizes and collaborate with contractors, distributors, and interior designers worldwide. We are proud to bring Vietnamese quality to the international market.

Cultured Marble is a smart material solution for modern living spaces, especially bathrooms. With seamless beauty, superior durability, waterproofing, easy maintenance, and reasonable cost, Cultured Marble offers high aesthetic and functional value.

Explore Vina PolyStone’s Cultured Marble product collection and experience the difference that Vietnamese quality brings to global projects.