Table of Contents

This cultured marble vanity top guide explores why, in today’s diverse world of interior materials, Cultured Marble has emerged as a smart choice that perfectly balances elegant aesthetics, practical functionality, and cost-efficiency. Whether it’s for a residential renovation or a commercial development, understanding this material opens the door to a wide range of design applications.

Let’s explore everything professionals need to know about Cultured Marble before reviewing the premium solutions offered by PolyStone.

Understanding Cultured Marble – A Complete Cultured Marble Vanity Top Guide

1. What is Cultured Marble?

Cultured Marble is an engineered composite material made by blending calcium carbonate powder with polyester resin and pigments. This mixture is poured into specially designed molds and coated with a protective surface layer called “gel coat.” The gel coat provides a hard, non-porous, glossy, and color-retaining finish that mimics the luxurious look of natural marble with added performance benefits.

2. How is Cultured Marble Made?

Understanding the manufacturing process provides insight into product quality. Cultured Marble is typically produced through the following steps:

- Mold Preparation: The mold is cleaned and coated with a release agent.

- Gel Coat Application: A colored or clear gel coat is evenly sprayed inside the mold, forming the outer surface.

- Mixing the Composite: Marble powder is blended with polyester resin and pigments to create custom colors and patterns.

- Casting: The mixture is poured into the mold on top of the gel coat.

- Curing: A chemical reaction hardens the mix into a solid structure.

- Finishing: Once cured, the product is removed, trimmed, polished, and quality-checked before delivery.

3. Versatile Applications of Cultured Marble

Thanks to its flexibility in production, Cultured Marble is widely used in interior environments, particularly in moisture-prone areas:

- Vanity Tops

- Shower Panels

- Bathtubs & Surrounds

- Shower Pans

- Window Sills, Fireplace Surrounds, and Decorative Trims

4. Pros and Cons of Cultured Marble

Every material has its strengths and limitations:

Pros:

- Cost-Effective: Typically less expensive than natural stone like granite or marble.

- High Customization: Available in a variety of colors, patterns, and shapes.

- Seamless Design: Integrated sinks reduce seams, simplifying cleaning and preventing bacterial buildup.

- Low Maintenance: Non-porous surface resists stains and requires no sealing.

- Repairable: Minor scratches or damage can often be repaired.

Cons:

- Susceptible to Scratches: Gel coat can scratch if exposed to sharp objects or abrasive cleaners.

- Heat Sensitivity: Direct heat contact may damage the surface.

- Inconsistent Quality: Product quality may vary depending on the manufacturer.

- Color Aging: Lower-grade products may yellow over time.

5. Popular Vanity Sink Designs

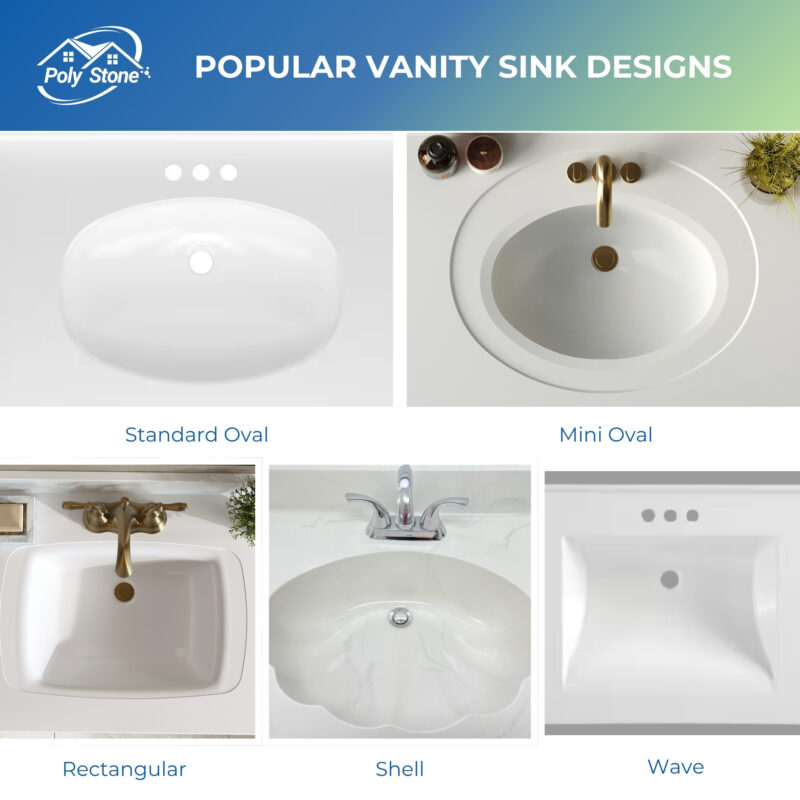

A key feature of Cultured Marble is the ability to create integrated sink designs that offer seamless aesthetics and a broad range of styles:

- Standard Oval: Timeless and soft, ideal for most bathroom designs.

- Rectangular: Sharp, clean lines perfect for modern environments.

- Shell: Decorative, ocean-inspired designs suited for classical or vintage interiors.

- Wave: Artistic basin with a sculpted, wavy bottom.

- Mini-Oval: Compact version of the oval sink, ideal for smaller vanities or guest bathrooms.

Color customization further allows for exclusive and distinctive product configurations.

6. Comparison with Other Countertop Materials

Here’s how Cultured Marble compares with other common countertop materials:

| Criteria | Cultured Marble | Natural Marble | Granite | Quartz | Solid Surface |

| Cost | Affordable | Very High | High | High | Medium to High |

| Maintenance | Low, no sealing needed | Very High, porous | High, needs sealing | Low, no sealing | Low, no sealing |

| Durability & Heat | Good but scratches easily; heat-sensitive | Poor durability | Very durable | Extremely durable | Good but heat-sensitive |

| Aesthetic | Highly customizable, seamless sink options | Unique natural beauty | Elegant stone patterns | Customizable, stone-like | Wide color range, can be thermoformed |

PolyStone – Elevating Cultured Marble Quality

Once the fundamentals of Cultured Marble are understood, the next question becomes: “How can businesses ensure consistent product quality and address the common drawbacks of this material?”

The answer is PolyStone.

At PolyStone, we don’t just produce Cultured Marble – we refine it. Our specialization in Cultured Marble Vanity Tops sets a new benchmark for both aesthetics and performance.

How Does PolyStone Improve Cultured Marble?

- Scratch & Yellowing Resistance: Our proprietary gel coat delivers superior hardness and clarity, ensuring lasting surface quality and color retention.

- Exceptional Consistency: European-standard manufacturing ensures batch-to-batch uniformity in color, resin ratio, and structural integrity.

- Enhanced Heat Resistance: Advanced gel coat formulation offers better thermal stability and reduces surface damage risks.

Choosing PolyStone Vanity Tops ensures long-term performance and consistent visual appeal.

Care Guidelines for PolyStone Products

To maintain pristine surface condition, clean with soft cloths and mild, pH-neutral detergents. Avoid abrasive tools or harsh chemical agents.

Watch our Stain Resistance Test: Cultured Marble Vanity Top Quality Control by PolyStone

Conclusion: A Strategic Upgrade for Interior Solutions

Cultured Marble is a compelling surface solution for modern construction and renovation projects, and PolyStone Vanity Tops represent the most refined version of this material. With timeless visual appeal, versatile customization, and enhanced durability, PolyStone products are backed by advanced manufacturing expertise.

Contact the PolyStone team today to request samples, technical specifications, or personalized consultation.