Table of Contents

I.The Engineering Behind PolyStone’s Gel-Coated Cultured Marble: A Renewable Surface

Choosing Gel-Coated Cultured Marble is the engineered answer to a major challenge in high-use environments like Hospitality Projects and Commercial Buildings: surface wear-and-tear. For most other materials, a scratch represents permanent damage leading to costly replacements, creating a significant “pain point” for asset owners.

However, PolyStone’s product offers a fundamental technical advantage: the inherent capability for surface renewal. This article will explain the technical structure and the process that allows our Gel-Coated Cultured Marble surface to be “healed.”

II. Real-World Proof: Watch the Demo

Before we detail the engineering, see the proof.

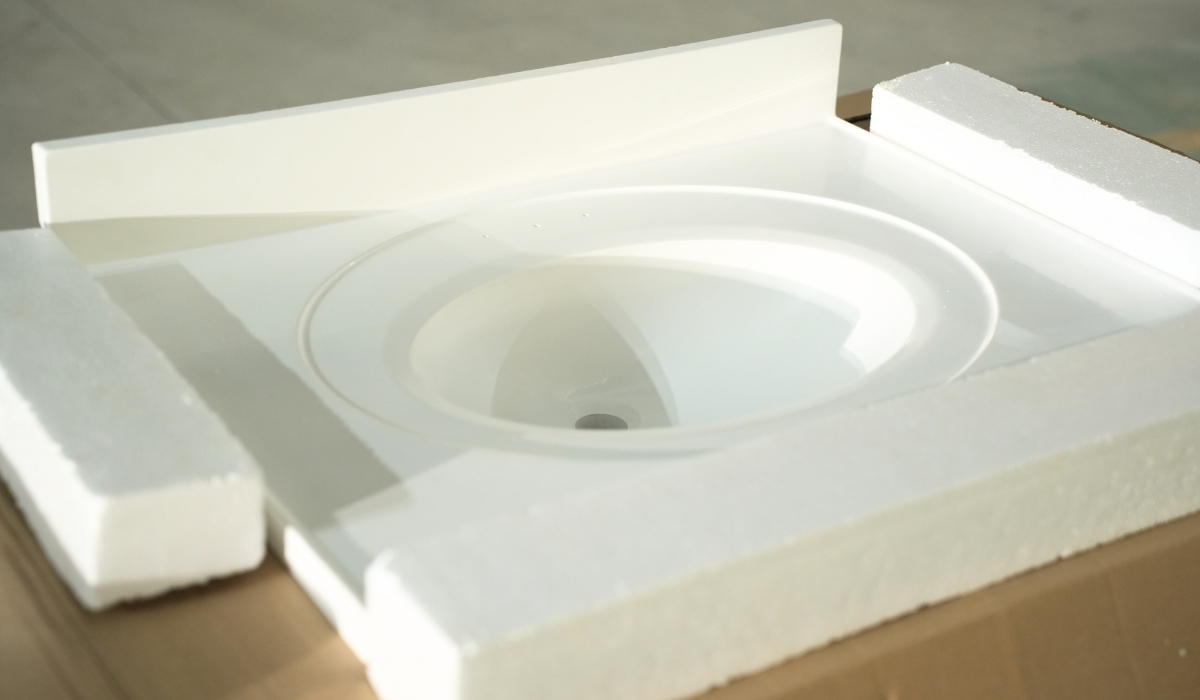

The video below is a real demonstration from our PolyStone factory, showing how a light scratch is completely removed from our standard Cultured Marble Vanity Top.

III. The Engineering: Why This Surface Can Be Renewed

The restoration capability you just saw is possible because of our unique manufacturing process.

- It is a Bonded Layer, Not Paint: The glossy finish on our products is not a thin layer of paint. It is a thick, multi-layer Gel-Coated Surface , creating a true Non-Porous Surface Treatment.

- One-Piece Casting: During our One-Piece Casting process, this gel coat is chemically bonded to the product’s core (a mix of calcium carbonate powder and resin). It becomes a single, solid part of the product.

- The Technical Key: Because this gel coat layer is thick and solid, a light scratch only affects the top of this layer. It does not penetrate through to a different material or color underneath. This is the key that unlocks the renewal capability.

This is a fundamental technical advantage of our standard Gel-Coated Cultured Marble surface.

IV. The Technical Process of “Renewing” the Surface

The restoration process, as seen in the video, is simple engineering.

- Sanding: Using fine-grit sandpaper, a technician gently sands the affected area. This action removes the scratch by leveling the gel coat surface.

- Buffing: Next, a standard polishing compound is used to buff the area. This restores the original factory gloss.

The surface is now back in its original condition. Because the gel coat is thick and consistent, this process simply reveals a fresh part of the same material.

V. Conclusion: Engineered Durability from PolyStone

This surface renewal capability is not magic. It is the result of advanced material engineering and a tightly controlled manufacturing process.

For Hospitality Projects and Commercial Buildings, this means a longer product life, a significant reduction in long-term maintenance costs, and a lower total cost of ownership.

Learn more about the technical benefits of our products.