Table of Contents

I. Introduction: Breaking the Supply Chain Bottleneck

In the OEM and Private Label industry, lead time is critical. For decades, the biggest bottleneck for new Cultured Marble Vanity Top designs has not been production, but mold fabrication.

B2B partners and project developers have been forced to accept an 8-10 week waiting period just to get a new mold. This delay often comes from a reliance on external tooling suppliers.

Today, PolyStone is proud to announce a strategic investment that changes this. We have achieved 100% in-house mold manufacturing capability. This move eliminates external dependencies and puts full control of the supply chain back in our partners’ hands.

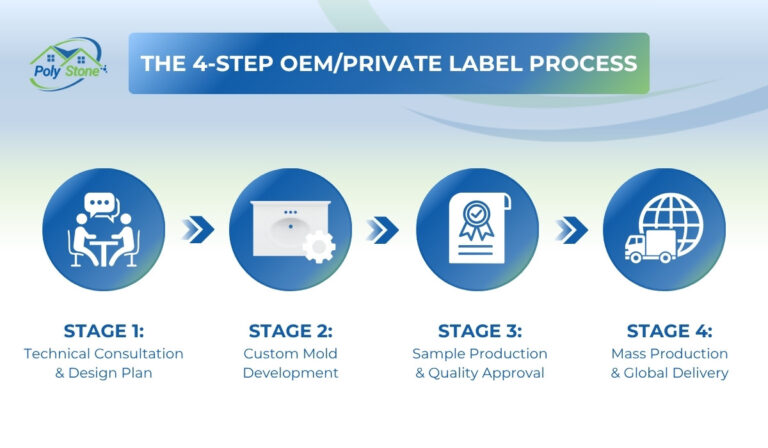

This post explains our in-house process and the three strategic benefits it delivers to your Custom OEM Projects.

II. Inside the PolyStone Mold Workshop: Where R&D Meets Manufacturing

Bringing mold fabrication “in-house” is more than just buying machines. It is a commitment to our R&D capabilities. Our process is built on precision and partnership.

- Step 1: R&D and Technical Consultation: Our R&D team works directly with you to optimize your technical drawings. We ensure every design is perfectly engineered for production.

- Step 2: CNC Machining & Fabrication: From the approved 3D model, our high-precision CNC machines begin fabricating the master mold.

- Step 3: Finishing & QC Testing: The mold is meticulously finished and inspected for perfect surface smoothness and dimensional accuracy. It is then tested before moving to mass casting.

III. 3 Strategic Benefits of In-House Mold Manufacturing for Cultured Marble Vanity Tops

This new capability directly translates into competitive advantages for our customers.

1. 50% Faster Lead Time – Get to Market Sooner

The impact is simple. What used to be an 8-10 week wait is now just 4-5 weeks. For urgent orders or tight project deadlines, this 50% reduction is a game-changer.

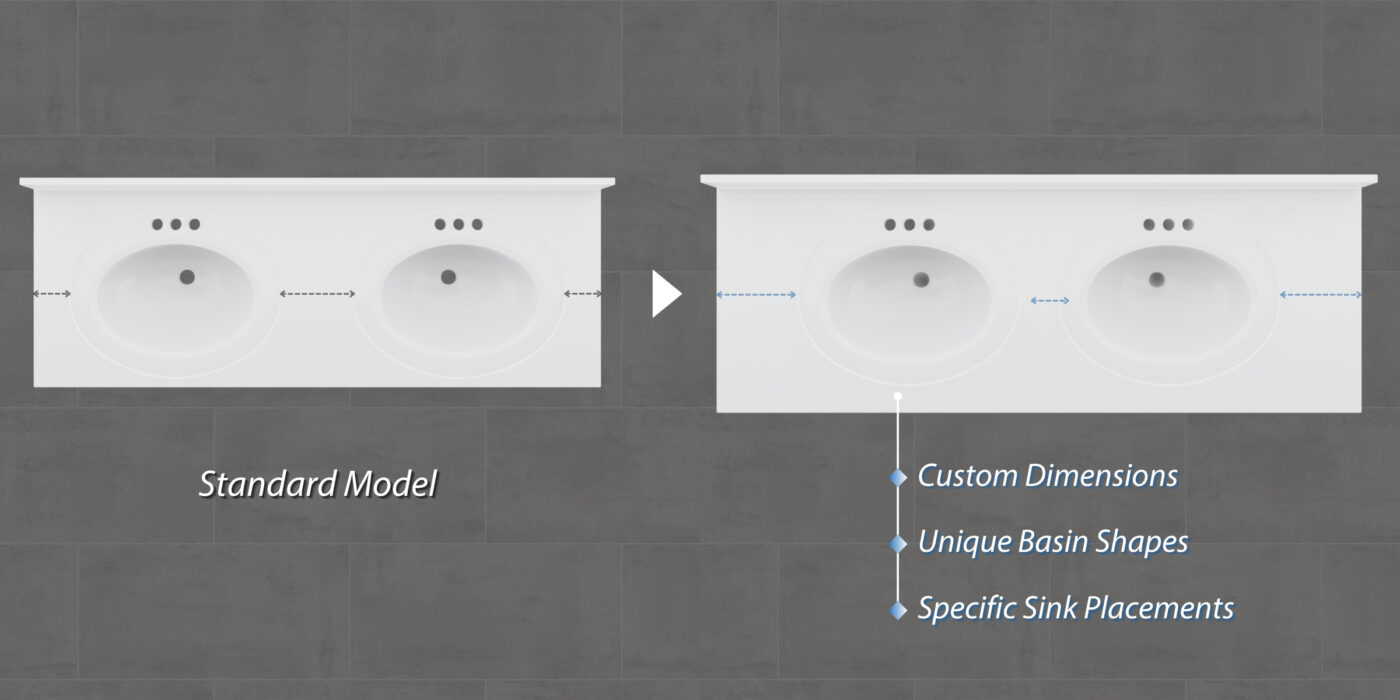

2. Advanced & Complex Customization

Controlling our own R&D and machinery unlocks a new level of customization. We can now easily manage complex requests, such as:

- Specific bowl placements (left-offset, right-offset).

- Unique rim and edge designs (e.g., 1-rim vs. 2-rim).

- Custom-sized vanity tops for specific projects.

3. Optimized Cost & Full Process Control

By removing external suppliers, we control the entire process17. This ensures technical consistency, protects your intellectual property, and optimizes operational costs—benefits that we pass on to you.

IV. Conclusion: PolyStone is Not Just a Manufacturer. We are Your R&D Partner.

Our investment in an in-house mold workshop is a clear commitment to our partners.

As a leading Vietnam Cultured Marble Manufacturer, we offer a complete, integrated supply chain. We control everything from the raw CaCO3 Powder to the mold fabrication and the final Casting Sanitary Ware product. We are not just a factory; we are your end-to-end technical partner.

Watch The Differences In PolyStone’s Vanity Top

Do you have an OEM project with complex technical requirements? Contact our R&D team today to start your project.