Table of Contents

Cultured marble vanity top quality control is at the core of everything we do at Polystone. We understand that when it comes to bathroom fixtures, quality is not just a feature—it is an expectation. That is why every product we manufacture undergoes a rigorous, multi-stage quality control process. Our goal is simple yet uncompromising: to deliver vanity tops that not only meet global standards but also withstand the realities of long-term use in real-life environments.

From design verification to post-production testing, our quality control system has been engineered to monitor and ensure excellence at every step.

Design Verification in Cultured Marble Vanity Top Quality Control

Before production begins, every project is subjected to a thorough design verification phase. Our engineering and quality teams jointly review all technical drawings and specifications to confirm accuracy, feasibility, and consistency with client expectations. This pre-production step is essential for preventing errors and ensuring smooth downstream operations. It reflects our commitment to proactive quality assurance—not reactive corrections.

In-Process Quality Control: Consistency Through Every Stage

Unlike many manufacturers that rely solely on final inspections, Polystone integrates quality checks into each stage of the production cycle. From the initial molding process to the final polishing and packing, our QC team actively monitors dimensions, surface condition, and curing quality.

This approach allows us to detect and resolve any deviation early in the workflow, helping us deliver a more consistent and reliable product—batch after batch, order after order.

Measurement and Visual Inspection: Detail That Matters

Following the molding and curing phases, each vanity top undergoes precise dimensional measurement. Our team uses calibrated tools to verify that all thicknesses, lengths, and widths meet the required tolerances. At the same time, a detailed visual inspection is conducted to identify any surface flaws such as uneven gloss, discoloration, pinholes, or micro-cracks.

This inspection phase ensures not only compliance with technical specifications but also upholds the aesthetic integrity that our customers expect from a high-end vanity product.

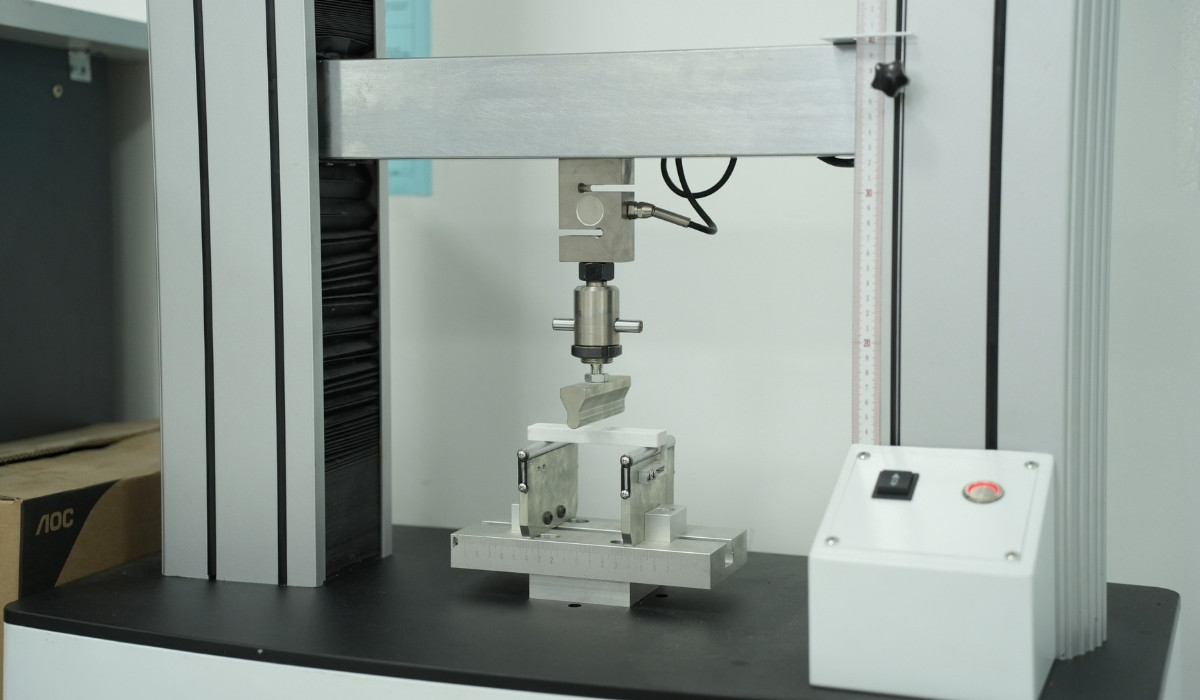

Mechanical Testing: Built for Strength and Longevity

To ensure that each vanity top performs reliably under regular use, we subject our products to a series of mechanical tests. These include impact resistance tests, where surfaces are exposed to sudden force to simulate accidental drops, and load-bearing strength tests that validate the product’s ability to support fixtures or applied pressure without deforming or cracking.

These tests are critical for assessing structural integrity—especially for commercial or high-traffic environments.

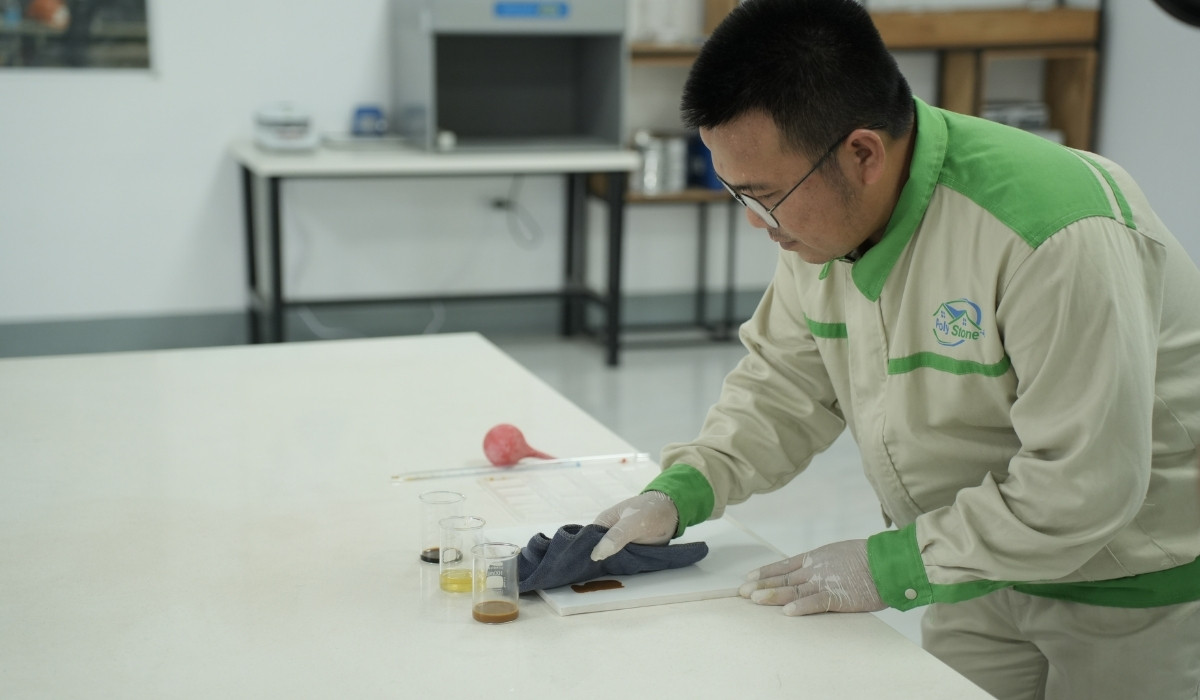

Stain Resistance Testing: Protection Against Daily Use

Bathroom surfaces must resist more than just time—they must also resist stains from everyday substances. Our stain resistance protocol includes dedicated tests for common household liquids such as coffee, tea, and soy sauce. During these procedures, we apply each substance to the surface for a specific duration, then assess the ease of cleaning and the surface’s ability to resist absorption or discoloration.

This stage confirms that our surfaces remain cleanable, hygienic, and visually appealing throughout years of use.

Moisture Resistance: Prepared for Humid Environments

Given the high-humidity conditions common in bathroom settings, moisture resistance is an essential quality indicator. We conduct moisture testing to ensure that no warping, swelling, or degradation occurs even after prolonged exposure to steam, splashes, or wet air.

Our materials and manufacturing processes are carefully selected to deliver long-term water tolerance, providing confidence to contractors, builders, and homeowners alike.

Final Quality Check and Secure Packaging

As the final step in our cultured marble vanity top quality control process, once all inspections and tests are completed, each vanity top is subject to a final approval round. Only units that meet every QC criterion are approved for shipment. Each product is then packed in reinforced wooden crates with edge protectors and steel supports, ensuring safe delivery over long distances.

Our packaging process is just as carefully considered as our production—because we believe quality should be preserved until the moment of installation.

A Quality Promise You Can Build On

At Polystone, our quality assurance process is not merely a routine. It is an integrated system built on expertise, experience, and attention to detail. From verifying design specifications to simulating real-world challenges, we take every possible measure to ensure that the product you receive is one you can trust.

When you choose Polystone, you are choosing a partner committed to durability, consistency, and customer confidence.

For technical specifications, detailed test data, or to request a sample, please contact our team. We are here to support your project from planning to completion—with quality that speaks for itself.

Watch video Behind the Scenes: How PolyStone Ensures Cultured Marble Quality